anchor

a quick diversion

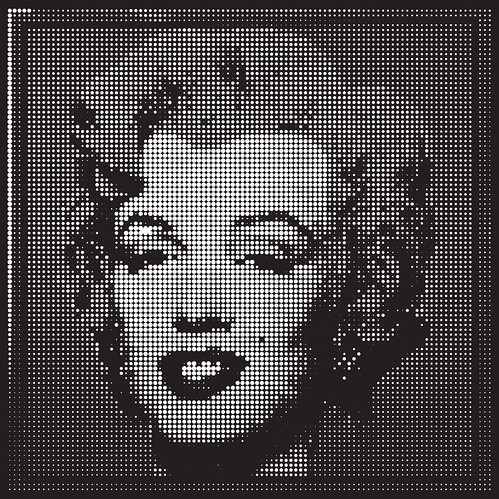

i needed a break from studio so i decided to tackle a problem that had been bothering me for a while....

if i wanted to lasercut (or mill) a perforated pattern, normally i'd take the image in photoshop, use the color halftone filter, take it into illustrator and use live trace, export to a dwg and cut it....

there were a few problems with this method. for one, the halftone generated in PS would have overlapping dots... in a field of black, for example, it would remain solid black. If you're cutting this, there's no material to keep the sheet together.

secondly, going through the illustrator live trace gives you distorted circles since it's interpolating from a raster image, so it's not ideal.

for this, i used rhino and grasshopper.... used create height field from image, extracted the points from the heightfield surface, then used grasshopper to scale a circle based on the relative height of each point, and put a limit on the maximum size (based on the initial grid of the image surface) so there would be no overlaps.

so. just a quick diversion. 12 days till pens down.

7 Comments

yeah, i've seen that, it gives you very little control.

scriptographer in illustrator could also be a quick solution.

There's probably a more elegant way of dealing with this through rhinoscript, but still sounds pretty useful. Any interest in sharing your grasshopper files?

i could. where's a good place to upload that sort of thing?

Evan,

I'd be really interested to see your Grasshopper files too. I'm teaching an introductory class on Rhino and digital fabrcation at Catholic University. I have some students studying the DeYoung museum and they were going to use Rasterbator, but if you've got a good Grasshopper solution I would love to share that with them.

Did you post this anywhere? Would you email it to me?

best,

Andrew Cocke

Hi Evan,

to produce a perforated pattern design for perforated metal project based on any digital image can be easily made by Image2Punch. Image2Punch is a software to convert digital image into perforated metal pattern. The hole pattern will be accurate and consistent as you can pre-determine the hole size for further uses in fabrication.

Please visit Image2PUnch software website on www.image2punch.com

regards,

Fransiscus Herry

Block this user

Are you sure you want to block this user and hide all related comments throughout the site?

Archinect

This is your first comment on Archinect. Your comment will be visible once approved.