This week's assignment for Witold's writing class was to write a review of an architecture exhibit, so I took Friday off to take a day trip up to New York to see the current show at the Museum of Modern Art. I'm just going to post a bunch of pictures here. If you want to read my somewhat critical review of the exhibit, you can read it here.

The sixth floor lobby.

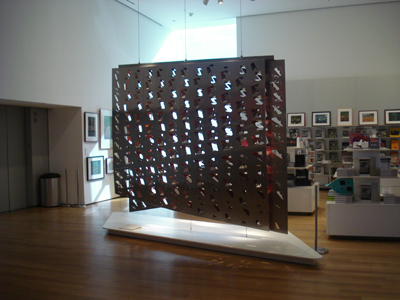

Marble Fairbanks' wall prototype.

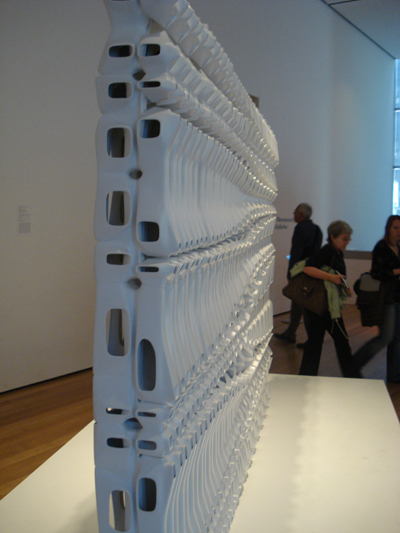

Ali Rahim & Hina Jamelle's wall prototype.

The sign outside.

Burst*008

The ribs of Burst*008 are inscribed with identifying marks.

A 2x4 crutch was added to the main staircase to stabilize it.

The other houses as seen from Burst*008's front porch.

The Micro Compact Home

The System3 House

The rear corner of the Instant House was done in plexi to reveal the construction system.

Instant House front stair.

The front porch of the Instant House

The Cellophane House

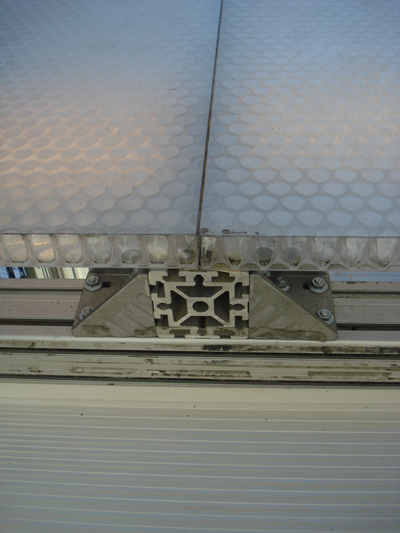

Floor detail of the Cellophane House.

Me, hanging out in Bryant Park after a long day at the museum.

Also, as part of the exhibition the five architects that built model homes were required to document the process on the Home Delivery Blog. Check it out.

5 Comments

I'm curious why you think Cellophane is more successful than Burst*. Did you know that Cellophane cost well over a million dollars to build, had the largest, most complex foundation work, and was the most difficult to put together on site? The people who assembled the prefabricated portions of the house (Kullman Building, in Lebanon, NJ) had to actually call the manufacturers of the curtain wall components in Germany and have them flown over to assist in the assembly. Burst was fabricated and assembled by a team of largely unskilled college students (I know, I was one of them), a few union carpenters, and cost less than half as much. Sure, some of the details got a bit sloppy, but when you consider the sheer amount of complexity that a ribbed structure like that poses, it's pretty astonishing the relative ease with which it came together in the end.

no offense podzilla, but i would say all the details were sloppy...

Hey PodZilla. I knew that you were on the team, so I debated about posting my critique. I hope that there are no hard feelings.

Of the five houses I was actually most excited to see Burst* and I was just disappointed to see how it was resolved. Like I said in my critique, I think that the underlying purpose of the show was illustrate possible future directions for prefabrication. In order for this to happen I think that it is important for the systems to be commercially viable. On this account, I think that all of the houses were by and large failures.

The "houses of the future" at World's Fairs and Breuer's house at MoMA in 1949 were all fully furnished and fully resolved houses that illustrated a new possible way of life for visitors. I can't imagine a layperson walking into any of the five houses on display and saying "I want to live here." While I appreciate the formal notions of the Burst* house, its rough detailing (and particularly the crutch holding up the stairs) were the most visible target for this critique.

On the other end of things, I think that the Cellophane House was by far the most refined example and the best example of a possible way to the future. That being said, I can't imagine the aluminum frame system ever being affordable enough for adoption into the mainstream. I think that Cellophane was also the most resolved in that it actually had a kitchen, restrooms, closets, etc. I was appalled by Burst*'s plywood box kitchen.

continued below... (i'm over my 2500 character limit)

Another criticism that I have of all of the houses but Cellophane was the integration of the ADA elevators. Given the parametric design process of Burst*, I thought that it was a missed opportunity to show how parametric models adjust to programmatic and site specific requirements. The elevator was a requirement for this site and the house should have adjusted to that requirement. Instead the elevator looked like an afterthought. It was a pink plywood wart stuck on the side of the house. It really seemed like the house was already built and then a code inspector came by and said "Hey, you need an elevator here!" so it was just added on to the side. This was true not only for Burst*, but for the Instant House as well.

Anyways, the piece that I wrote for class was only supposed to be 500 words. The final version that I submit on Tuesday is actually about 700. It originally was about 900 and I could have easily written about 2000. Like I said, I think that there were a lot of admirable things in the show, but as part of the bigger picture, I think that it was a bit of a failure.

No hard feelings, for sure. I agree that Burst had its fabrication problems- stemming mainly from the fact that the original aussie version was laser cut while this one was cut on CNC routers, which are a completely different beast. Many, many of the nested sheets we received from the architects to be cut contained extraordinarily tiny parts (some less than 1/2") that were basically vaporized by the router bit upon being cut. I feel that they were shooting for too much precision- like what they received with the original laser cut version- and therefore didn't spend the time to rework things properly. A perfect example of this were the actual burst flower appliques on the exterior facade. Those were cut from single sheets of plywood into 1/2" strips using a 1/2" router bit. As anyone who has worked with a router knows, getting that thin in plywood is always dangerous, hence we lost quite a few of those strips. We could have achieved a very similar effect using pocket cuts- like the ones on the burst windows- but the architects wanted the full depth of the 5/8" plywood. As to the crutch under the stairs- I remembered those stairs being bouncy on the night of the opening party... I suppose that's just a structural failure from the beginning. The elevators were horribly resolved, yes, in fact I remember cutting the sheets that enclose the burst elevator several days after we had been told that the cutting was done. I can almost guarantee you that a situation with a code official similar to what you mentioned above occurred. Maybe what we've all learned from this show is that it is exceptionally difficult to strike a balance between a beautifully detailed prefab box (system3) and the complex formal language of the burst system. What's really interesting to me is your "layperson" comment- I actually visited the houses a couple days ago with my parents and grandparents. My parents were more impressed that I had worked on the team building this thing and wanted to take my picture in front of everything, while my grandparents were walking around saying things like "where are the doors?" "why are there no screens on these windows?" "this kitchen is too small" etc. In that regard, the Breuer house, with its full set of furnishings, was far far more successful in giving a picture of how someone might actually live in one of these spaces.

Block this user

Are you sure you want to block this user and hide all related comments throughout the site?

Archinect

This is your first comment on Archinect. Your comment will be visible once approved.