Being in Australia, I have had limited cold-climate design experience (think insulated slabs, in-floor heating, etc.).

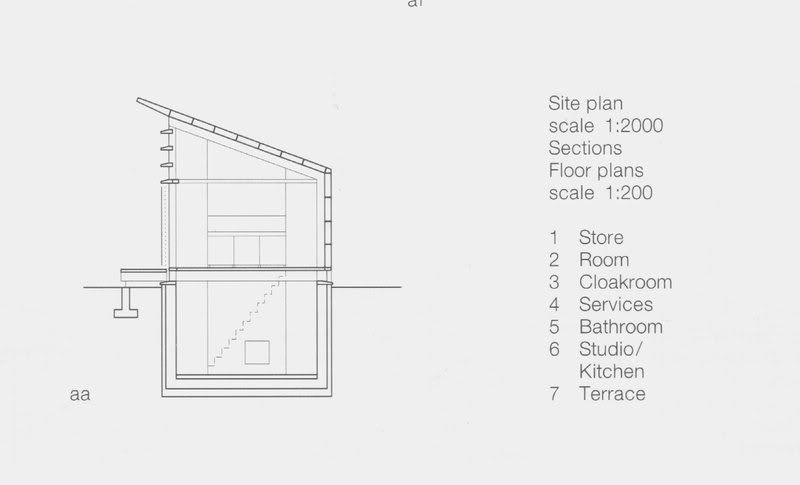

Anyway, I'm drafting up a section of an existing pavilion in Amsterdam from the fragments in a detail magazine. One element that they have largely neglected is the slab/walls that enclose the sub-terrain basement.

From the 1:200 snapshot, it appears that the the 15mm fibre-cement board & 100mm extruded polystyrene insulation (on the outside of the 250mm explosed concrete plinth wall) continue to the underside of the slab. Perhaps not the fibre-cement board, but the insulation certainly appears to do so.

The slab also appears to be weight-bearing, as there are no associated raft edges or footings. My question is, how can there be polysterene insulation on the underside of a weight-bearing slab? Would this not greatly sacrifice the structural integrity of the slab/building over a period of time?

I'm just about to detail this building the building with the insulation above the slab (beneath the panel flooring, inbetween the joists/bearers), unless someone can shed some light on the issue!

hmmm...it's a little hard to tell from your images, but typically in the offices i've worked we would insulate the foundation walls with rigid insulation and then only the outer two feet of the underside of the slab, not the enter underside of the slab. typically heat loss through the underside of the slab is minimal relative to the walls. because nothing is labelled or hatched in your drawings i wonder if what you're seeing underneath the slab is the granulated fill and not insulation. in my opinion, if it is a thick layer of insulation, it is completely unnecessary.

also, even if it is a load bearing wall, the foundation detail looks odd to me. i would have a perimeter footing that's supporting the wall and a non-structural slab.

i wouldn't call above drawing a foundation detail. it is more like a diagram for a magazine, there is not enough detail to build the proposed building unless it is some kind of vernacular building.

i don't understand why insulation would compromise a retaining/foundation wall?

but here are two drawings i found in the web that are closer to reality, even though i don't get the second slab on the first one and second one does not show polypropylene (plastic sheet) over the sand as moisture barrier, not to mention the gravel and perforated pipe doesn't show as noted.

i don't think there is one typical detail which is universal when it comes to slab and retaining wall details since climate/temperature, soil and construction conditions vary from one region to the other not to mention local building technics.

a lot of illustrations in detail magazines are for design intent only. don't take them too literally.

i hope this helps a little.

I have no idea how you could ever form up and pour such a condition as you have shown.

1. Excavation full basement area + area to work and set

foundation forms. Foundation to wall width 3 to 1. Typical depth

width of foundation wall. Provide continuous keyway in top

of footing and also provide continuous steel rebar in footing. This

will help the footing span any areas where compaction is not at

an approporiate level and you have settling. You should

also provide vertical rebar dowels in the foundation they will be

sticking up out of the foundation. There purpose is to tie the

foundation wall to the footing and to provide reinforcing to the

foundation wall were it is retaining.

2. Strip foundation forms and set in-place foundation wall forms. They

sit directly on top of footing. They will also have continuous rebar

at the bottom of the wall and also at the top of the wall. This

makes the wall work like a big beam so if any settling occurs

the loads can be tranfered to where it is bearing. Depending upon

the height of the wall you will also be required to place additional

vertical foundation rebar and horizontial rebar for retaining

purposes. Pour the concrete into forms, flost top of wall then set

anchor bolts in wet concrete. Let sit for a day then strip forms and

leave wall for seven days. Waterproof your exterior face of

foundation wall, apply Closed Cell Polystyrene insulation

to the exterior of the wall. You can take it all the way down to the

top of the footing or just to the frost line. It all depends what you

are planning to do with heat. If your using radiant heat go all the

way down. If your looking for mass for solar heat sink go all the

way down. The more mass you have in a building the less

flucutation you will have in temparture.

3. The floor slab system will be your next agenda.

4. First you must be sure you have a good aggregate base course

below your concrete slab. Engineers like less Excavators like

more. I personally go with more. It should be put into place

after you have installed all of your rough plumbing and any other

below floor conduits. Then it should all be compacted in lifts as

required.

5. Once you have your base in place you can install your undeslab

insulation.There is a product which you can put under the floor

which is what I would call superior to 2" Rigid Closed Cell

polystyrene insulation. 3. There is a product which you can put

under the floor which is wha I would call superior to 2" Rigid

Closed Cell polystyrene insulation. Because it does two things, it

is a vapor barrier and you don't have all these cracks between

boards every 2' and 8'. I2" Boadst are also very subject

breakage because it is stiff material. The product I would

recommend is: http://www.thebarrier.com/index.php

They actually discuss the product in a manner where I'm

sure it is everybit as good as the old way of doing things. I just

love innovation.

5. Place your metal woven wire fabric in the bottom third of the slab

with your radiant heat tubes.

6. Pour your concrete floor, bull float and trowel finish.

7. Provide Footing Drains as required around the perimeter of

foundation footings as required.

Do you want to tell me how you would form up your project inorder to pour concrete?

even those details above aren't showing insulation, but they should be if you are building in a cold climate. at minimum you should have 2" rigid insulation outside the foundation wall and take care to detail the first floor joists (or slab) so as not to create a thermal bridge between the insulated foundation and the first floor wall insulation. in addition, perimeter insulation under the slab i still believe to be best practice.

just noticed that you are using a radiant flooring system. i'm not sure if that changes the game for insulating the entire underside of the slab or just the perimeter. perhaps. snook's link seems like a good reference.

re: the colored diagrammatic detail,

it may be just a clean crawlspace with good attention placed to keeping moisture out; the insulation may be intended to occur in the framed floor assembly.

re: detail 6,

usually the slab rests on a thickened edge so that there is unexcavated (or at least recompacted fill) keying the interior edge of the footing to keep it from sliding to the interior from the exterior soil pressure - depending upon the amount of retainage. The thickened edge provides for the depth of the granular fill.

perhaps that 1" of rigid insul will eventually end up as 1/2".....

I put in a slab floor like that a while ago - It wasn't for a basement floor. It was for the first floor of a building. We used 2" rigid insulation. Laid it right over the compacted earth. Put the wire mesh over the rigid. We raised the mesh about 1" over the sheets of insulation using spacers. We were also installing radiant heating - so we zip tied the radiant tubing to the mesh. Then we poured the concrete. For the footings we also used the rigid. We also used the rigid insulation as stay-in-place forms in certain areas.

Jafidler is right. Not that it matters. There would be little need for insulation below the slab as compared to the walls, especially since the slab is significantly below grade.

I will mention that I'm a relatively young student of this profession so if you could dumb-down your posts a bit it would help greatly (I truly struggled to interpret your post, snook_dude, but thanks heaps for taking the time!).

I guess I may have taken the 1:200 snapshot too literally - perhaps it is more diagrammatic than honest.

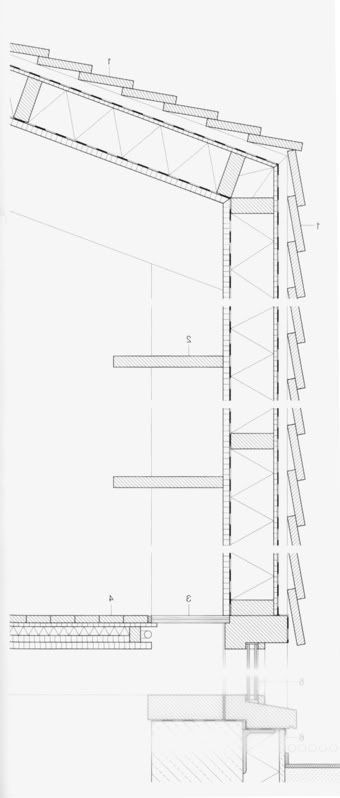

However, I will add this 3D section produced by the architects. I have scaled it to ~300% so you can see that the rigid insulation has been hatched on the underside of the slab in the manner I was proposing in my first post. I still don't understand how this can be structurally feasible, without (as some of you have pointed out) a footing system that would take the load of the walls, and allow the slab to be non-structural:

Just to confirm, ^^^ this wouldn't have actually been how the basement was constructed, yes?

Personally, I am not that happy with the some elements of detailing. However, I am supposed to draft the builiding, and only interpolate when there are any gaps in information.

Having said that, how should I detail this slab and walls?

A combination of the two sections as posted by Orhan Ayyüce seem like a fairly logical solution. Would adding rigid insulation to the underside of the (non-structural) slab, above the sand/campact fill be feasible? It will also be added to the outside of the walls, as keeping with what I already know from the detail section.

Also, should the basement slab sit directly on the external footing as shown in the second diagram, or above the slab as shown in the first? I think somebody mentioned it above, but should I thicken the edge of the slab where it meets/sits above the footing? (and have the insulation sit inbetween the thickened edges)

Thanks for the responses guys, we're getting there!

i would usually do as in 2nd version, though in slightly different way (would pour slab to edge of wall ; wall would then sit on top of slab). i would also insulate under the slab with rigid insulation.

the diagram you show seems a bit odd to me, but one never knows. i'd just call the architects and ask them to explain. that would be the easiest and best way to find out what is really going on.

don't know if it is any use, but if interested you can see process of pouring slightly sunken foundation here. it is for a house recently finished in tokyo. you can see where the insulation is inserted under slab and how walls and slab meet, etc, if you go to bottom of screen and work your way up.

the blog shows entire construction process start to finish over 7-8 month period. if interested in seeing how it came out just keep going through blog backwards...

my interpretation of their diagram is that the insulation is on the exterior of the foundation and below the slab (without any footings). I'd also guess that the floor is furred up above the slab...

hmmm... after looking at the 3d view, second thoughts- that the exterior hatched layer is a drainage system/gravel fill/compacted sub-grade. still they need some sort of footing for most soil conditions unless they've built on bedrock -then the excavation costs are $$$$$ for solid rock to carve out that basement.

i was looking at some drawings, it's actually probably really close to that diagram. the one i am looking at shows a (roughly) 8" conc. slab that is flush with the external walls, the basement walls are keyed into this slab. perimeter insulation all the way up and under as well as gravel fill/drain.

i think this system is not uncommon, i'll post a pic in a sec.

are you really taking a rendered 3d section as a construction detail. Do you realize some slack jawed intern probably did that rendering and didn't have the best grasp on foundation details? do you want me to start pointing out some other problems with it? the floor package seems suspect and those clouds are making my eyes hurt. eye candy seems to keep popping into my head. snook_dude had a great written explanation...kind of blows my mind that an architect can explain a construction detail without drawing anything. i suggest responding to any RFI's in a similar manner.

jjh, you could be correct, but to be honest i wouldn't publish a dwg that was incorrect anywhere if it was my own office. young interns don't always do quality control, but the boss does. i do anyway.

as holz shows it is entirely possible the 3d section is correct. looks good to me.

it is also possible to make a slab thicker than normal instead of building a footing. if it were me i would show the compacted/prepared gravel or soil extending 100mm from edge of slab on both sides in a construction drwg, but for the 3d model this seems quite enough...

what jfidler says. note that the concrete guys don't like putting rigid insul under the slab...it creates problems during the construction process, as esp. in residential applications the ground may not be fully compacted, and it is tough to put this on rough ground, and they don't like walking on it. the insul likes to try to float on the concrete and breaks up when you step on it. sometimes they substitute a "miracle" foil backed bubble wrap, easier to install but it doesn't insulate for shit. we tend to spec it under the entire slab where i am, if it is for radiant heat application. it won't fully insulate, but will provide some "reflective" heat return, ensuring the slab heats more quickly at first. after that the system relies on the thermal mass of the slab.

You can always glue the edges of rigid sheets together using foamboard adhesive. This will help to prevent the insulation from floating. You can drive rebar spikes throught the rigid and let them stick out a couple of inches. Then tie the mesh to the spikes about an inch over the rigid. This will also help to prevent floating.

i see welded wire mesh in slab details (sic) the new concrete body says NO on that any longer, use natural fibers and expansion joints with tapered bracing

also we do slabs out of 50lbs EPS with a GFRC skin per the new ICC of SABS ESR-1638 that i posted last week, so sure it would work, just use less cement more fibre and more

I've skimmed much of the above, so excuse me if I've missed it, but are you sure this is a site-poured foundation? Maybe it's a pre-cast concrete box sunk into the ground and backfilled? The ground floor building - from the 3D colored rendering - looks like it could be a pre-fab structure, brought in and dropped on a pre-installed foundation box.

The basement level is basically acting like half a pipe at this point, right, so would be better at keeping out water than the typical keyed wall/footing connection. Maybe there is some soil condition that would benefit from this, though I can't imagine what it would be - I've just got images of Safdie's Habitat bouncing in my brain.

Go ahead and tell me if I sound high, guys, as you all know this stuff much better than I do.

holz/jump, sure, you could detail the foundation that way, but why would you ever want to. there's a reason why footings look the way they do. if you're placing the foundation wall on a slab without a footing, chances are pretty good you're going to have cracks forming in that slab. you could thicken the slab to compensate, but why waste all that concrete when you could just use a footing? it's not even a "design" decision; it's a matter of detailing in a way that is both efficient and effective.

for a large slab i would say not such a good idea, but for a small enough room/building it can make sense to just thicken the slab and save the hassle of making a footing. it may be different in other countries but here the ground is compacted with sand and gravel before a slab goes in, so a footing becomes less efficient than a thickened slab.

ti be fair. since this is earthquake country when i say footing i actually mean grade beam, but those can be turned sideways as it were and accomodated in a thickend slab...it depends on the soil conditions and other issues as well...but there is no a priori rule that says a footing per se is a requirement. this may be an example where it worked without a footing.

would be interesting to hear from the architects what is the real story.

I’m just saying that it isn’t uncommon. Those working in the EU might be able to give more insight… p2an around?

On smaller projects with really light evenly distributed loads, a thickened slab may be more efficient than footings, from an excavation and materials standpoint.

Like LB, I've skimmed this over so apologies if I've missed things. To return to the original poster's question: if it's not a prefab as lb suggests, then it may be possible that the insulation is filled between some kind of supporting joist structure that runs parallel to the section.

i think the half pipe idea sounds close to right. need more structural info but from the drawings it appears the floor does not brace the foundation walls--perhaps they are acting like retaining walls in conjunction with a structural slab/footing.

if so its a nice idea.

about the soil conditions, phased mentions the location is Amsterdam, so it must be clay. Usually a deep foundation is used with concrete piles. These piles rest on a stable sand layer which usually can be found 20 to 30 meters down in the ground. This means foundations are expensive in the Netherlands.

In presentations drawings these piles are often left out.

btw. I think lb might be right about prefab.

Polystyrene insulation beneath weight-bearing slab?

Hi guys,

Being in Australia, I have had limited cold-climate design experience (think insulated slabs, in-floor heating, etc.).

Anyway, I'm drafting up a section of an existing pavilion in Amsterdam from the fragments in a detail magazine. One element that they have largely neglected is the slab/walls that enclose the sub-terrain basement.

From the 1:200 snapshot, it appears that the the 15mm fibre-cement board & 100mm extruded polystyrene insulation (on the outside of the 250mm explosed concrete plinth wall) continue to the underside of the slab. Perhaps not the fibre-cement board, but the insulation certainly appears to do so.

The slab also appears to be weight-bearing, as there are no associated raft edges or footings. My question is, how can there be polysterene insulation on the underside of a weight-bearing slab? Would this not greatly sacrifice the structural integrity of the slab/building over a period of time?

I'm just about to detail this building the building with the insulation above the slab (beneath the panel flooring, inbetween the joists/bearers), unless someone can shed some light on the issue!

I will try to scan a few pics up.

Many thanks.

asdf

Here is the broad 1:200 overview:

And here you can just see the top of the basement walls/slab:

Thanks for any help!

hmmm...it's a little hard to tell from your images, but typically in the offices i've worked we would insulate the foundation walls with rigid insulation and then only the outer two feet of the underside of the slab, not the enter underside of the slab. typically heat loss through the underside of the slab is minimal relative to the walls. because nothing is labelled or hatched in your drawings i wonder if what you're seeing underneath the slab is the granulated fill and not insulation. in my opinion, if it is a thick layer of insulation, it is completely unnecessary.

also, even if it is a load bearing wall, the foundation detail looks odd to me. i would have a perimeter footing that's supporting the wall and a non-structural slab.

i wouldn't call above drawing a foundation detail. it is more like a diagram for a magazine, there is not enough detail to build the proposed building unless it is some kind of vernacular building.

i don't understand why insulation would compromise a retaining/foundation wall?

but here are two drawings i found in the web that are closer to reality, even though i don't get the second slab on the first one and second one does not show polypropylene (plastic sheet) over the sand as moisture barrier, not to mention the gravel and perforated pipe doesn't show as noted.

i don't think there is one typical detail which is universal when it comes to slab and retaining wall details since climate/temperature, soil and construction conditions vary from one region to the other not to mention local building technics.

a lot of illustrations in detail magazines are for design intent only. don't take them too literally.

i hope this helps a little.

I have no idea how you could ever form up and pour such a condition as you have shown.

1. Excavation full basement area + area to work and set

foundation forms. Foundation to wall width 3 to 1. Typical depth

width of foundation wall. Provide continuous keyway in top

of footing and also provide continuous steel rebar in footing. This

will help the footing span any areas where compaction is not at

an approporiate level and you have settling. You should

also provide vertical rebar dowels in the foundation they will be

sticking up out of the foundation. There purpose is to tie the

foundation wall to the footing and to provide reinforcing to the

foundation wall were it is retaining.

2. Strip foundation forms and set in-place foundation wall forms. They

sit directly on top of footing. They will also have continuous rebar

at the bottom of the wall and also at the top of the wall. This

makes the wall work like a big beam so if any settling occurs

the loads can be tranfered to where it is bearing. Depending upon

the height of the wall you will also be required to place additional

vertical foundation rebar and horizontial rebar for retaining

purposes. Pour the concrete into forms, flost top of wall then set

anchor bolts in wet concrete. Let sit for a day then strip forms and

leave wall for seven days. Waterproof your exterior face of

foundation wall, apply Closed Cell Polystyrene insulation

to the exterior of the wall. You can take it all the way down to the

top of the footing or just to the frost line. It all depends what you

are planning to do with heat. If your using radiant heat go all the

way down. If your looking for mass for solar heat sink go all the

way down. The more mass you have in a building the less

flucutation you will have in temparture.

3. The floor slab system will be your next agenda.

4. First you must be sure you have a good aggregate base course

below your concrete slab. Engineers like less Excavators like

more. I personally go with more. It should be put into place

after you have installed all of your rough plumbing and any other

below floor conduits. Then it should all be compacted in lifts as

required.

5. Once you have your base in place you can install your undeslab

insulation.There is a product which you can put under the floor

which is what I would call superior to 2" Rigid Closed Cell

polystyrene insulation. 3. There is a product which you can put

under the floor which is wha I would call superior to 2" Rigid

Closed Cell polystyrene insulation. Because it does two things, it

is a vapor barrier and you don't have all these cracks between

boards every 2' and 8'. I2" Boadst are also very subject

breakage because it is stiff material. The product I would

recommend is: http://www.thebarrier.com/index.php

They actually discuss the product in a manner where I'm

sure it is everybit as good as the old way of doing things. I just

love innovation.

5. Place your metal woven wire fabric in the bottom third of the slab

with your radiant heat tubes.

6. Pour your concrete floor, bull float and trowel finish.

7. Provide Footing Drains as required around the perimeter of

foundation footings as required.

Do you want to tell me how you would form up your project inorder to pour concrete?

even those details above aren't showing insulation, but they should be if you are building in a cold climate. at minimum you should have 2" rigid insulation outside the foundation wall and take care to detail the first floor joists (or slab) so as not to create a thermal bridge between the insulated foundation and the first floor wall insulation. in addition, perimeter insulation under the slab i still believe to be best practice.

the footing detail is correct however.

just noticed that you are using a radiant flooring system. i'm not sure if that changes the game for insulating the entire underside of the slab or just the perimeter. perhaps. snook's link seems like a good reference.

OA shows it all except the insulation.

re: the colored diagrammatic detail,

it may be just a clean crawlspace with good attention placed to keeping moisture out; the insulation may be intended to occur in the framed floor assembly.

re: detail 6,

usually the slab rests on a thickened edge so that there is unexcavated (or at least recompacted fill) keying the interior edge of the footing to keep it from sliding to the interior from the exterior soil pressure - depending upon the amount of retainage. The thickened edge provides for the depth of the granular fill.

perhaps that 1" of rigid insul will eventually end up as 1/2".....

I put in a slab floor like that a while ago - It wasn't for a basement floor. It was for the first floor of a building. We used 2" rigid insulation. Laid it right over the compacted earth. Put the wire mesh over the rigid. We raised the mesh about 1" over the sheets of insulation using spacers. We were also installing radiant heating - so we zip tied the radiant tubing to the mesh. Then we poured the concrete. For the footings we also used the rigid. We also used the rigid insulation as stay-in-place forms in certain areas.

Jafidler is right. Not that it matters. There would be little need for insulation below the slab as compared to the walls, especially since the slab is significantly below grade.

to meet passivhaus standards, the underslab insulation should be about 70% roof insulation for optimization.

also, if you are using hyronics, you'll want it to be insulated.

Thanks for the responses guys.

I will mention that I'm a relatively young student of this profession so if you could dumb-down your posts a bit it would help greatly (I truly struggled to interpret your post, snook_dude, but thanks heaps for taking the time!).

I guess I may have taken the 1:200 snapshot too literally - perhaps it is more diagrammatic than honest.

However, I will add this 3D section produced by the architects. I have scaled it to ~300% so you can see that the rigid insulation has been hatched on the underside of the slab in the manner I was proposing in my first post. I still don't understand how this can be structurally feasible, without (as some of you have pointed out) a footing system that would take the load of the walls, and allow the slab to be non-structural:

Just to confirm, ^^^ this wouldn't have actually been how the basement was constructed, yes?

Personally, I am not that happy with the some elements of detailing. However, I am supposed to draft the builiding, and only interpolate when there are any gaps in information.

Having said that, how should I detail this slab and walls?

A combination of the two sections as posted by Orhan Ayyüce seem like a fairly logical solution. Would adding rigid insulation to the underside of the (non-structural) slab, above the sand/campact fill be feasible? It will also be added to the outside of the walls, as keeping with what I already know from the detail section.

Also, should the basement slab sit directly on the external footing as shown in the second diagram, or above the slab as shown in the first? I think somebody mentioned it above, but should I thicken the edge of the slab where it meets/sits above the footing? (and have the insulation sit inbetween the thickened edges)

Thanks for the responses guys, we're getting there!

i would usually do as in 2nd version, though in slightly different way (would pour slab to edge of wall ; wall would then sit on top of slab). i would also insulate under the slab with rigid insulation.

the diagram you show seems a bit odd to me, but one never knows. i'd just call the architects and ask them to explain. that would be the easiest and best way to find out what is really going on.

don't know if it is any use, but if interested you can see process of pouring slightly sunken foundation here. it is for a house recently finished in tokyo. you can see where the insulation is inserted under slab and how walls and slab meet, etc, if you go to bottom of screen and work your way up.

the blog shows entire construction process start to finish over 7-8 month period. if interested in seeing how it came out just keep going through blog backwards...

my interpretation of their diagram is that the insulation is on the exterior of the foundation and below the slab (without any footings). I'd also guess that the floor is furred up above the slab...

hmmm... after looking at the 3d view, second thoughts- that the exterior hatched layer is a drainage system/gravel fill/compacted sub-grade. still they need some sort of footing for most soil conditions unless they've built on bedrock -then the excavation costs are $$$$$ for solid rock to carve out that basement.

i was looking at some drawings, it's actually probably really close to that diagram. the one i am looking at shows a (roughly) 8" conc. slab that is flush with the external walls, the basement walls are keyed into this slab. perimeter insulation all the way up and under as well as gravel fill/drain.

i think this system is not uncommon, i'll post a pic in a sec.

are you really taking a rendered 3d section as a construction detail. Do you realize some slack jawed intern probably did that rendering and didn't have the best grasp on foundation details? do you want me to start pointing out some other problems with it? the floor package seems suspect and those clouds are making my eyes hurt. eye candy seems to keep popping into my head. snook_dude had a great written explanation...kind of blows my mind that an architect can explain a construction detail without drawing anything. i suggest responding to any RFI's in a similar manner.

jjh, you could be correct, but to be honest i wouldn't publish a dwg that was incorrect anywhere if it was my own office. young interns don't always do quality control, but the boss does. i do anyway.

as holz shows it is entirely possible the 3d section is correct. looks good to me.

it is also possible to make a slab thicker than normal instead of building a footing. if it were me i would show the compacted/prepared gravel or soil extending 100mm from edge of slab on both sides in a construction drwg, but for the 3d model this seems quite enough...

what jfidler says. note that the concrete guys don't like putting rigid insul under the slab...it creates problems during the construction process, as esp. in residential applications the ground may not be fully compacted, and it is tough to put this on rough ground, and they don't like walking on it. the insul likes to try to float on the concrete and breaks up when you step on it. sometimes they substitute a "miracle" foil backed bubble wrap, easier to install but it doesn't insulate for shit. we tend to spec it under the entire slab where i am, if it is for radiant heat application. it won't fully insulate, but will provide some "reflective" heat return, ensuring the slab heats more quickly at first. after that the system relies on the thermal mass of the slab.

You can always glue the edges of rigid sheets together using foamboard adhesive. This will help to prevent the insulation from floating. You can drive rebar spikes throught the rigid and let them stick out a couple of inches. Then tie the mesh to the spikes about an inch over the rigid. This will also help to prevent floating.

i see welded wire mesh in slab details (sic) the new concrete body says NO on that any longer, use natural fibers and expansion joints with tapered bracing

also we do slabs out of 50lbs EPS with a GFRC skin per the new ICC of SABS ESR-1638 that i posted last week, so sure it would work, just use less cement more fibre and more

expanded polystyrene

I've skimmed much of the above, so excuse me if I've missed it, but are you sure this is a site-poured foundation? Maybe it's a pre-cast concrete box sunk into the ground and backfilled? The ground floor building - from the 3D colored rendering - looks like it could be a pre-fab structure, brought in and dropped on a pre-installed foundation box.

The basement level is basically acting like half a pipe at this point, right, so would be better at keeping out water than the typical keyed wall/footing connection. Maybe there is some soil condition that would benefit from this, though I can't imagine what it would be - I've just got images of Safdie's Habitat bouncing in my brain.

Go ahead and tell me if I sound high, guys, as you all know this stuff much better than I do.

LB - I think you are right - I wonder how something like this would work?

holz/jump, sure, you could detail the foundation that way, but why would you ever want to. there's a reason why footings look the way they do. if you're placing the foundation wall on a slab without a footing, chances are pretty good you're going to have cracks forming in that slab. you could thicken the slab to compensate, but why waste all that concrete when you could just use a footing? it's not even a "design" decision; it's a matter of detailing in a way that is both efficient and effective.

for a large slab i would say not such a good idea, but for a small enough room/building it can make sense to just thicken the slab and save the hassle of making a footing. it may be different in other countries but here the ground is compacted with sand and gravel before a slab goes in, so a footing becomes less efficient than a thickened slab.

ti be fair. since this is earthquake country when i say footing i actually mean grade beam, but those can be turned sideways as it were and accomodated in a thickend slab...it depends on the soil conditions and other issues as well...but there is no a priori rule that says a footing per se is a requirement. this may be an example where it worked without a footing.

would be interesting to hear from the architects what is the real story.

I’m just saying that it isn’t uncommon. Those working in the EU might be able to give more insight… p2an around?

On smaller projects with really light evenly distributed loads, a thickened slab may be more efficient than footings, from an excavation and materials standpoint.

whoa

Like LB, I've skimmed this over so apologies if I've missed things. To return to the original poster's question: if it's not a prefab as lb suggests, then it may be possible that the insulation is filled between some kind of supporting joist structure that runs parallel to the section.

I may be way off though.

i think the half pipe idea sounds close to right. need more structural info but from the drawings it appears the floor does not brace the foundation walls--perhaps they are acting like retaining walls in conjunction with a structural slab/footing.

if so its a nice idea.

about the soil conditions, phased mentions the location is Amsterdam, so it must be clay. Usually a deep foundation is used with concrete piles. These piles rest on a stable sand layer which usually can be found 20 to 30 meters down in the ground. This means foundations are expensive in the Netherlands.

In presentations drawings these piles are often left out.

btw. I think lb might be right about prefab.

if its NL i wouldn't be surprised at all. much concrete construction there is pre-fab. p2an will know best.

Block this user

Are you sure you want to block this user and hide all related comments throughout the site?

Archinect

This is your first comment on Archinect. Your comment will be visible once approved.